Control and measurement are fundamental pillars for optimizing production levels in any industry. In this case, a prominent Colombian steel company faced a critical challenge: accurately determining the amount of tons processed per hour in its shredder. To overcome this limitation, they turned to the specialized team at Caproin.

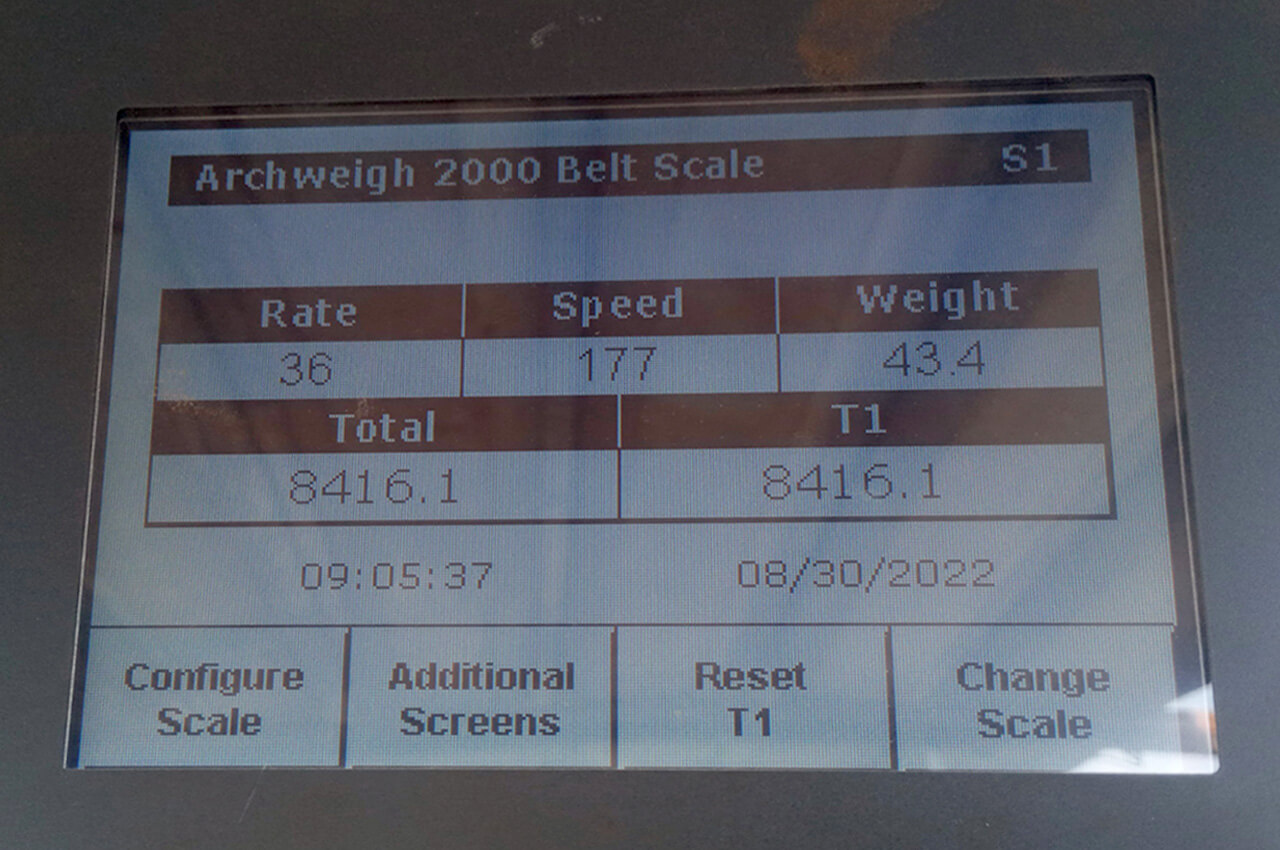

With the implementation of an online dynamic weighing scale from the ARCH brand, represented in Colombia by Caproin S.A., the company managed to transform its measurement processes and obtain real-time information about its daily, monthly, and annual productivity. This advancement not only eliminated tentative and inaccurate estimates but also allowed for a more detailed analysis of key indicators such as productivity, downtime, operator performance, and results per operating shift.

The challenge

The company is dedicated to manufacturing essential construction inputs, such as steel rebars and corrugated iron, which are crucial for civil works, buildings, housing, and more, made from recycled scrap metal.

The head of the preparation area needed to accurately identify the productivity of raw materials processed in tons per hour. However, traditional methods presented significant limitations:

These methods lacked accuracy and hindered key strategic decisions.

The solution

Caproin S.A, installed an ARCH online dynamic weighing scale, a solution specifically designed for the client’s technical and operational needs. The equipment, equipped with a touchscreen and a digital system (PLC), allows for real-time measurement of the weight of the processed material, data archiving, and accurate billing.

This advancement allowed:

Impact on operations

Thanks to the ARCH scale, the company achieved:

By installing an ARCH scale, they were able to determine which operators were most skilled and had optimal shredder handling, leading to a training plan that improved the productivity of the preparation area.

Step-by-step process

Caproin received the challenge posed by the client.

A technical evaluation was carried out at the facilities.

The ideal solution, based on the ARCH dynamic scale, was presented.

In collaboration with ARCH, technical details were adjusted to guarantee effectiveness.

The client obtained digital and real-time measurements of their daily productivity.

Conclusion

This success story reflects Caproin’s commitment to innovative solutions that transform industrial processes. With the installation of the ARCH dynamic scale, the steel company not only achieved a new level of precision in its measurements but also gained a clearer and more controlled vision of its business.